What is Kishu lacquerware? The history and characteristics of Kishu lacquerware are explained.

Do you know what Kishu lacquerware is?

Kishu lacquerware is one of the traditional crafts handed down in Wakayama Prefecture, and the key point is that it can be used as a practical product and is also full of functional beauty.

Kishu lacquerware has evolved with the times thanks to the skilled techniques of craftsmen who have passed down the art of lacquerware from generation to generation, right down to its functional beauty and practicality.

Kishu lacquerware has a long history and many characteristics, so it will be easier to become familiar with it if you take a look at its history and learn about its features.

Let us explain the history and characteristics of Kishu lacquerware.

What is Kishu lacquerware?

Kishu lacquerware is one of the traditional crafts handed down mainly in the Kuroe area northwest of Kainan City, Wakayama Prefecture, and is so magnificent that it is called one of the three major types of lacquerware in Japan, along with Aizu lacquerware from Fukushima Prefecture and Yamanaka and Wajima lacquerware from Ishikawa Prefecture.

It can be said that only the skill of skilled craftsmen can produce such magnificent lacquerware.

Kishu Lacquerware Production Process

The production process of Kishu lacquerware is divided into four main processes: the woodworking process, the undercoating process, the painting process, and the decorating process.

Wood base process

In the wood base process, the raw materials are processed and dried, and then processed into one of the following types: round, plate, square finish, hot-water bending, and itsukage.

Once the raw material is cut to a certain size, it is left to stand until the moisture is gone and it is no longer deformed.

The key is to use a saw or a canner, if necessary, to create the shape of a heavy box and other finger-shaped items.

Groundwork Process

In the groundwork process, wood preparation, grounding, and ground grinding are performed.The shape of the substrate in the wood base process is repaired and maintained.

Top Coating Process

In the painting process, primer coat, middle coat, middle coat grinding, and top coat are applied.

The key point of this process is to achieve higher durability and a beautiful finish by performing the primer, middle coat, middle coat grinding, and top coat processes.

Decorating Process

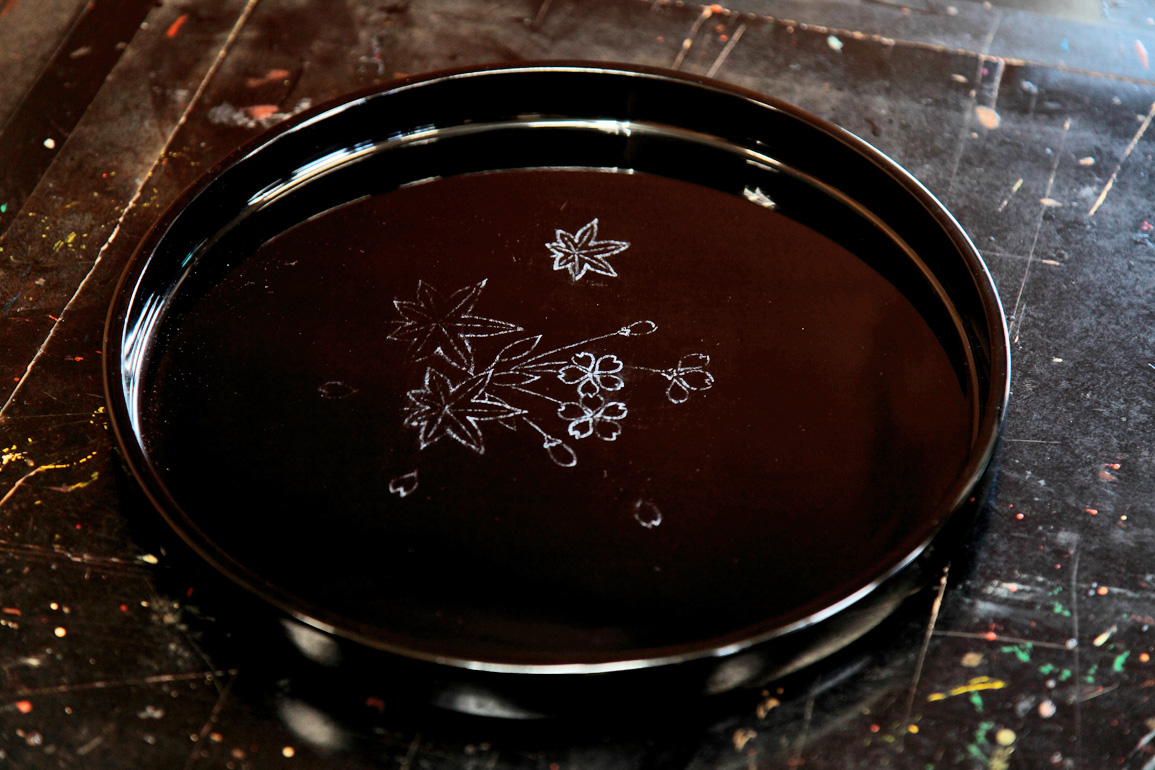

In the decoration process, maki-e chinkin and other processes are used to create products.

In the decoration process, gold and colored urushi are used to decorate each product by hand after it has been painted in the previous processes. This is where the skill and sense of the craftsman are tested, and each craftsman’s individual characteristics will come out.

When producing resin products, four processes are involved: pressing, polishing, painting, and decorating.

Pressing, polishing, painting, and decorating processes

In the pressing process, the raw resin is injected into a mold and formed under heat and pressure.

In the polishing process, the resin surface is polished to improve the adhesion between the paint and resin.

In the painting process, urethane paints called “Food Sanitation Law clear paints” are used to finish the product surface beautifully.

In the decoration process, substitute gold powder is used for the painted product, and the product is precisely printed by machine.

Basically, Kishu lacquerware is produced using a machine, resulting in a uniform and beautifully finished Kishu lacquerware.

History of Kishu Lacquerware

The history of Kishu lacquerware is said to have begun in the Muromachi Period.

It is said that Kishu lacquerware began in the Muromachi period when Kishu woodworkers made Shibuji bowls, and further influenced Kishu lacquerware by Negoro-nuri, which was used by monks at temples to make their own items, including the tables and bowls used by the monks.

Negoro-nuri is a method of finishing the wooden base of bowls and chairs with black lacquer for the middle coat and vermilion lacquer for the top coat.

Because Negoro-nuri was not naturally produced by craftsmen, the lacquer was unevenly applied, and the vermilion quality peeled off to expose the black lacquer.

However, because shu and black urushi were later regarded as quaint bowls and sets because of their good appearance, products with the shu lacquer stripped off seem to have been produced on a dare.

In 1585, when Toyotomi Hideyoshi, known for his unparalleled love of tea ceremony utensils, attacked Negoro-ji Temple, where a priest was said to have been engaged in Negoro-nuri, Kishu lacquerware spread when he escaped difficulty at Kuroe.

In the Edo period (1603-1867), it developed under the protection of the Kishu Tokugawa clan. In the process of development, a thorough division of labor was established among the woodworkers, groundworkers, and lacquers, and Kuroe flourished as a major lacquerware production center with more than 1,200 lacquerware-related businesses.

Originally, before the Edo period, there were no lacquerware merchants in Kuroe and not much lacquerware was distributed there, which made it possible to mass-produce lacquerware at low cost.

Then, in 1826, the production of hard-ground board items such as tables was successful, and from 1852 to 1860, they were decorated with maki-e lacquerware. The company continued to develop further, selling directly to foreign merchants visiting Nagasaki and Kobe.

However, when the Meiji Restoration began, the Kishu-Tokugawa clan lost its protection due to the abolition of feudal domains, but by 1870, the company began full-scale overseas trade, which restored the vitality that had been on the verge of decline.

In 1898, a maki-e lacquerware maker from Kyoto was invited to Kishu to improve maki-e techniques.

The export value of lacquerware gradually declined as it reached its peak in the middle of the Meiji period (1868-1912), but in the Showa period (1926-1989), various lacquering techniques were introduced, such as Tendo-nuri and silk lacquer, and the industry continued to develop and evolve.

In 1949, Kuroe became an important lacquer industrial park, and in 1978, Kishu lacquerware was recognized as a national traditional craft.

Characteristics of Kishu Lacquerware

Kishu lacquerware has the following characteristics

- The more it is used, the more tasteful it becomes.

- High strength makes it easy to last for a long time

Let us explain the characteristics of Kishu lacquerware.

The more you use it, the more you appreciate its charm.

The greatest characteristic of Kishu lacquerware is that the more it is used, the more its charm is felt.

The more it is used, the more it becomes more elegant and shows a different aspect, which is a very big advantage of Kishu lacquerware.

Basically, the more you use lacquer ware, the more luster it acquires and the better the colors become.

○The high strength of the product makes it easy to last for a long time.

Kishu lacquerware is coated with black lacquer and then red lacquer, which efficiently increases the strength of the lacquer.

The longer it is used, the shinier and more elegant it becomes, so it does not deteriorate easily even if it is used for a long time in daily life.

The lacquer solution originally used for Kishu lacquerware has excellent durability against water and heat. The main ingredient, urushiol, oxidizes and hardens in climates with moderate humidity, so high strength can be achieved depending on the processing.

In particular, raw lacquer that has been harvested will be refined and filtered to increase its purity, which may add further strength.

How to use Kishu lacquerware

Kishu lacquerware is basically durable, so some people may not have any problems with it without being aware of it.

However, it can be made to last even longer by using it with proper awareness.

When using Kishu lacquerware, avoid the following actions

- Avoid prolonged exposure to sunlight, high temperatures, or water

- Do not heat over an open flame, in a microwave oven, or in an oven

- Wash with a soft sponge dipped in neutral kitchen detergent

- Do not leave items with moisture in them.

- After washing, wipe off water carefully with a soft cloth.

Many people may use lacquerware in various ways because it is strong, durable, and resistant to water and heat, but if the lacquerware is used recklessly and put under strain, it will deteriorate in no time.

Please do not use lacquerware recklessly.

Conclusion

Kishu lacquerware is one of the traditional crafts with a history of more than 400 years, and the more it is used, the more it becomes shiny and tasteful due to the contrast of black and vermilion lacquer.

If you are interested in Kishu lacquerware, why not try it?

Reference: Welcome! To Kishu Lacquer Ware Home Page

Reference: Traditional Craftsman of Kishu Lacquer Ware

-300x300.jpg)